Case Study: An Open and Shut Case

uPVC window machinery manufacturer chooses Matara linear motion products

SNAPSHOT

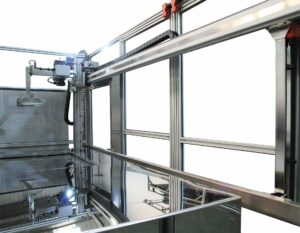

Matara linear rails and guides, and SFNHR precision ballscrews, supplied to bespoke automation company for new CNC Corner Transom Machine for uPVC Double Glazed Windows. The XY linear system at the heart of the machine allows for tight tolerances and can be programmed to accommodate 100 different positions.

APPLICATION

ABOUT: Pernamatic Engineering

Established in 1996, Pernamatic Engineering provides professional, reliable precision engineering services, with a focus on the uPVC window industry, for which it provides window machinery and consumables and a complete range of support services, including servicing, repairs, and plc upgrades and programming.

The company also specialises in the design, manufacture and installation of prototype machinery and conveyor systems, and offers water jet cutting services.

THE REQUIREMENT: Linear motion system for uPVC Window Corner Cleaner

Since the company’s inception, Pernamatic Engineering has designed and manufactured specialist uPVC window machinery including Corner Cleaners, utilising the latest technology available. Unlike timber and aluminium windows that are held together with pins, screws and glue, uPVC windows have welded mitre joints.

The frame then becomes a single, homogenous product, making them exceptionally strong, as well as being more cost-effective to produce. As part of this process, the surface weld sprue needs to be removed to improve the aesthetic appearance.

To do this by hand is a very laborious manual process using several hand tools. For one Pernamatic Engineering customer it was taking 15 minutes for an operator to finish each corner. Whilst Pernamatic Engineering have an off the shelf EPH-3 CNC Corner Cleaner which provides an automatic weld cleaning solution, a bespoke solution was required for this particular customer, which would require a new XY linear system.

THE SOLUTION: XY linear system featuring Matara compact linear rails and guides, and precision ballscrews

Matara has been working with Pernamatic Engineering for over five years, supplying pneumatics and linear motion products. When the company approached us with a design for an XY linear system for a new CNC Corner Transfer Machine for UPVC Double Glazed Windows, we were able to meet their exact needs, and from standard stock for a quick delivery.

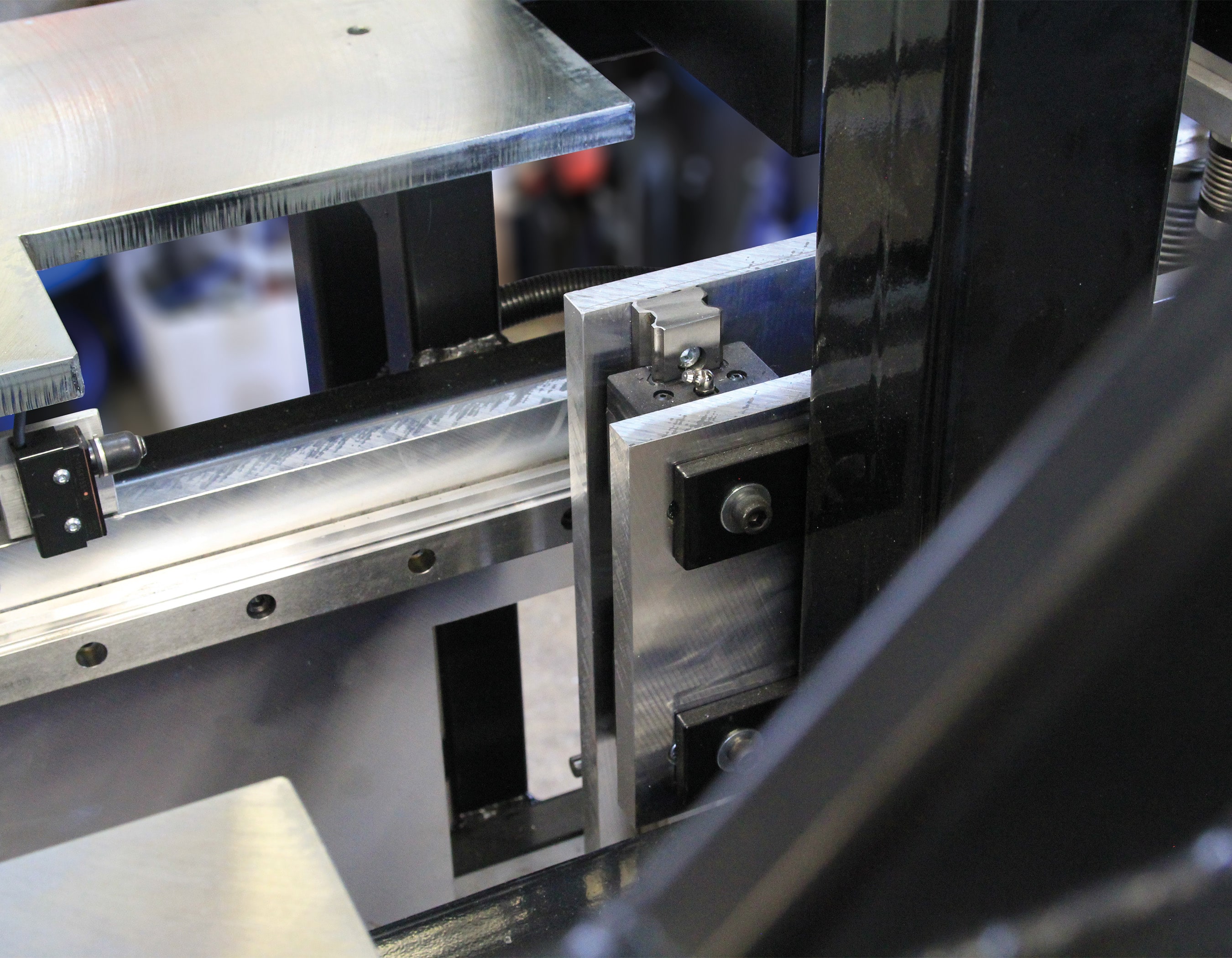

At the heart of the new machine is an XY linear system which uses Matara MSB compact 35mm type linear rails and guides and SFNHR precision 20mm ballscrews which position the internal radius tool to 80 different programmable positions.

The MSB Series is renowned for its compact nature whilst maintaining a quiet and smooth motion. It features a 45° contact angle to bear an equal load in radial, reversed radial and lateral directions, along with high rigidity, four-way equal load and self-alignment capability.

The ballscrews, which are machined in-house at Matara, suit the fixed ballscrew end supports which give the ballscrew excellent rigidity. Additional benefits of using Matara linear ballscrews include high efficiency due to reduced friction during use, high load capacity at fast speeds, and cost-efficiency.

The resulting CNC Corner Transfer Machine for UPVC Double Glazed Windows is both flexible and fast. It is capable of handling 200 different UPVC window frame configurations and finishes a complete frame in just 80 seconds. It is also highly accurate as the Matara linear rails and guides allow the machine to position the tool to 0.016mm tolerances.