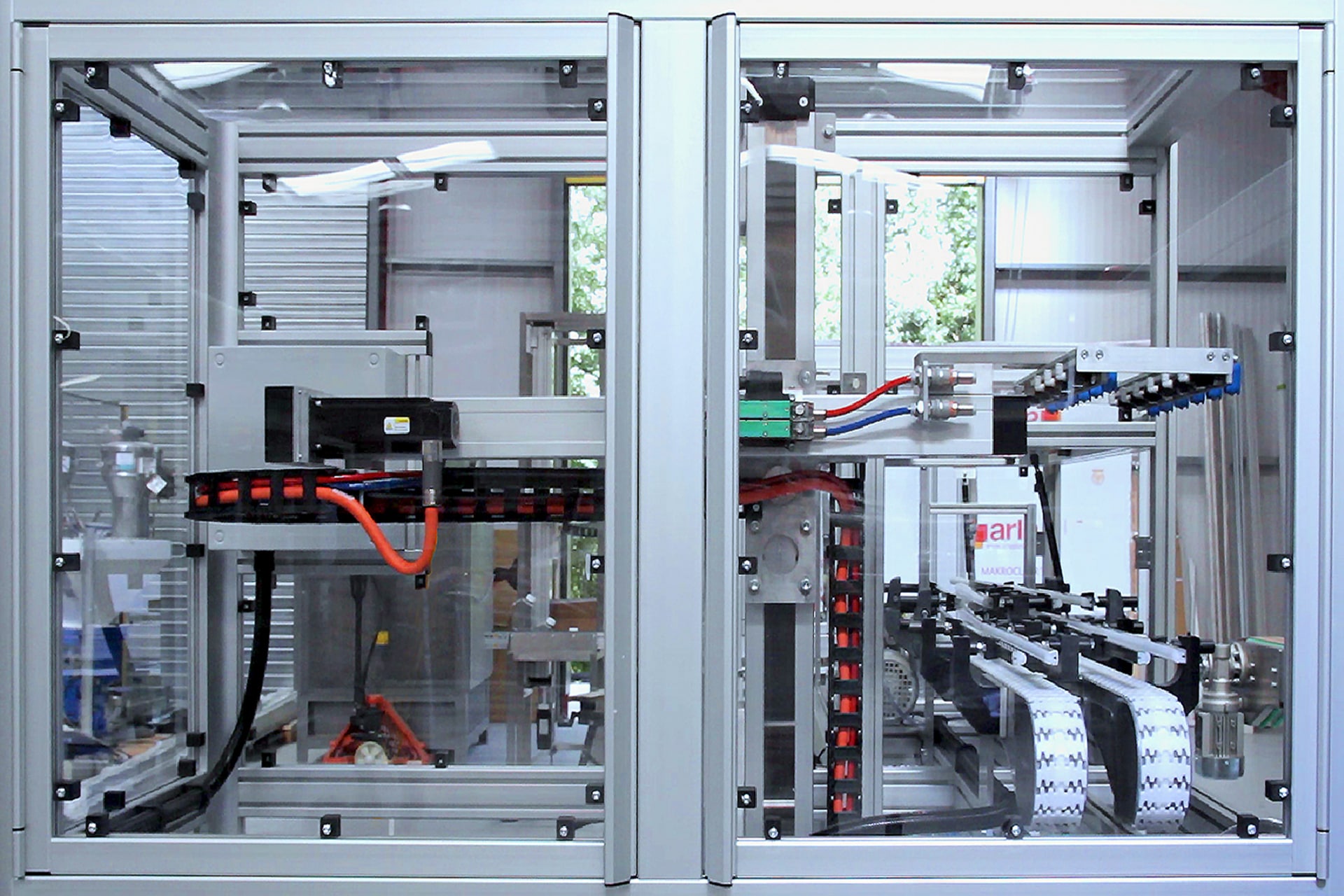

Matara’s MTV Actuators provide a dynamic linear motion solution for bespoke bottle filling machines

The application required 750mm and 650mm stroke in X & Y axis, to pick and then place varying sizes of medical bottles. The bottles would be loaded onto the tray and then placed onto the conveyor to travel to the next line of production. The specified actuators needed to be repeatable to within 0.03mm and had to be quiet and smooth in its 24 hours a day running cycle.

Matara’s size 80 & 110 MTV ballscrew actuators were specified for the job. With repeatability of 0.02mm and proven PMI & TBI linear rails and ballscrews inside, the lifetime and functionality of the actuators was more than adequate for the application.

These compact, low maintenance actuators save time in design as they are ready to mount and specifically designed for simple fitting of stepper or

servo motors, a key benefit for the OEM and the end user alike.

Although the application didn’t require any great speed or load being applied, the customer wanted the option of increased output so the MTV, capable of achieving speeds of more than 1.5m a second and dynamic load capacity of over 3000kg again proved a good option.

The end user predicts that more than a million containers will pass through this newly automated line every year, massively increasing output and reducing the need for manual handling and human error in the process.

The initial install and immediate payback has meant that the end user will require at least another two lines.