Matara supplies converting solutions provider with machine guarding

What is the purpose of a machine guard?

Machine guards are a crucial piece of safety equipment for any piece of machinery operated by a human. They are the first line of defence from any injuries, and all machine guards should create a physical barrier preventing the person operating from having any part of their body in a danger zone. They should always be secured in place and strong to ensure nobody can bypass or tamper with the machine guard.

A machine guard is a valuable piece of safety equipment in any workplace. At Matara, we work with T S Converting to supply the best Matara guard framing to keep all workers safe and able to operate at maximum efficiency.

A NEW CONVERT

SNAPSHOT

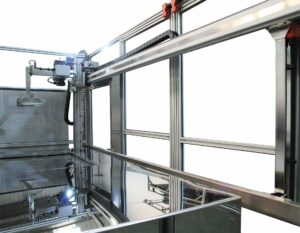

Matara manufactures aluminium machine guard framing for T S Converting, a world leading manufacturer of slitting, coating, and lamination machinery. The Matara machine guard framing has saved the manufacturer valuable production time and looks highly professional, which is appealing to its customers.

ABOUT: T S Converting Equipment Ltd (Elite Cameron)

T S Converting Equipment Ltd (Elite Cameron) specialises in innovative solutions for slitting, coating and lamination of a wide range of substrates. The company provides tailored designs that suit customers’ requirements, often incorporating roll handling, packing and transportation solutions. Shipping all around the globe, T S Converting is a world leader and continues to grow, with teams both in the UK and USA.

THE REQUIREMENT: Machine perimeter safety guards

With machinery that takes continuous rolls of sheet materials and processes them into a final product using ultra sharp cutting blades, hot adhesives, and even, on occasion, high pressure water, safety is paramount. Ensuring people do not get too close to the machinery when in operation, and to ensure compliance with safety regulations, a physical machine guard needs to be placed around each machine. T S Converting supplies customers with a complete solution, which includes not only the machinery but also the protective guard frame.

Before employing the services of Matara, T S Converting used to produce the guard frames in the house. It would buy full lengths of aluminium extrusion and full sheets of mesh, and its engineers would cut them down to size and assemble it themselves. Understandably, this was a very time-consuming process and also a costly one, as the type of aluminium extrusion chosen was an unusual size (44 mm x 44 mm) and more expensive. Furthermore, it did not have a tapping hole in the end, meaning a number of accessories, such as screw in feet or castors, could not be used.

T S Converting turned to Matara in 2021 to outsource the machine guard frame production, saving its engineers valuable time to focus on their core work of machine building.

THE SOLUTION: Cost-effective, professionally produced machine guard framing

With a range of machines sold by T S Converting and with each customer having their own set of requirements, including the premises’ size and layout, each frame guard system is bespoke. T S Converting supplies Matara with CAD drawings for each machine order, which our design engineers view on our SolidWorks solid modelling CAD software.

From here, we cut the extruded aluminium profile to the correct size and then assemble the guarding panels to T S Converting’s exact specifications. Aluminium is our metal of choice for this customer due to its adaptability, speed of production, and cost-effectiveness when compared to steel.

T S Converting’s latest project with us involved over 200m of 40x40mm aluminium profile, powder coated safety yellow (RAL1003). All sections of this guarding have been supplied with UK stocked 25×25 black powder coated wire mesh or clear polycarbonate panels.

A wide range of alluminum profile accessories have been included in the machine guard design, including feet for mounting the sections to the floor for stability, connecting plates complete with fixings, door handles, and hinges. With T-slots pre formed into the aluminium profile, adding further accessories couldn’t be easier, as they simply slide into these slots without the need for welding or drilling holes. This has enabled T S Converting to make further on-site adaptations, including adding pneumatic switches and panels to certain areas of the profile as well as safety switches on the doors of the guard frame.

Commenting on their decision to outsource machine guard frame production to Matara, James Self, Director at TS Converting Equipment, said: “One of the main reasons we chose Matara is the time it has saved us in production. We now have the guarding cut, powder coated, and fully assembled, saving our engineers valuable time in our busy production schedule. The guarding has been a huge success, not just for saving money but also for how smart it looks.” T S Converting has also been impressed with the service Matara has delivered: “The service provided by Matara has always been helpful and professional.

Every member of staff at Matara has always been welcoming and more than happy to help. Because of the success of guarding, we are now discussing other areas of the business that we can work together on. The partnership between T S Converting and Matara has a very bright future.”

If you wish to learn more about us at Matara, you can look through our technical articles for advice on a huge range of machinery or take a look at our other case studies to learn all about the value that we provide for our customers.