An introduction to ball screws

Ball screws are top of the class when it comes to linear motion control solutions that provide precision and efficiency. Find out more about how ball screws work, why they are so popular, and what kinds of considerations you should factor in when selecting the right ball screw assembly for an application.

Why are ball screws so popular?

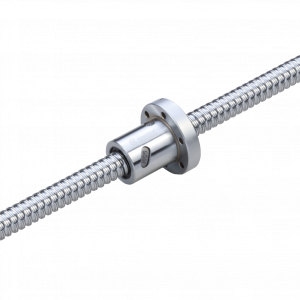

Ball screws are made up of a nut and threaded shaft with hardened steel ball bearings that move on a helical pathway to drive the motion. This use of ball bearings negates much of the friction associated with other screws such as roller and acme, and this lack of friction means that ball screws are 90% efficient or higher, and therefore one of the most effective ways of turning rotary motion into linear motion. Not only does the design of the ball screw make it efficient, it also makes it capable of moving heavy loads quickly, making it a rival for pneumatic and hydraulic cylinders. Ball screws are also the linear motion system of choice for high-precision applications because their movement, including acceleration and deceleration, is controllable with high levels of accuracy.

How to select the right ball screw for your application

There are a range of ball screw options on the market, and when selecting the configuration for a particular assembly, a number of factors should be considered. These include:

Loads:

Dynamic and static loadings both need to be calculated. Dynamic load ratings are usually based on a given load that can be moved for a million revolutions. Moment loads are also important, with particular focus on the direction in which they occur because they are likely to reduce the efficiency of the ball screw.

Service life:

There are a number of calculations used to estimate the likely life expectancy of a ball screw. Experienced ball screw suppliers such as Matara UK are able to support you in the calculation of these, either online or via their engineering support team.

Speed:

The speed of movement for a ball screw can depend on a number of factors including mounting method, diameter, unsupported length and the rpm speed. Screw straightness and the alignment of the assembly will also be factors in speed calculations.

Accuracy:

Ball screws can be manufactured using two different methods: rolled or ground. Rolled screws are generally less expensive and also manufactured with lower accuracy levels, whereas ground screws are higher in terms of accuracy but also come at a higher cost.

Environment:

The operating environment may affect factors such as protective coatings, bellows and seals. This is because ball screws are often used in plants where dust and debris are produced, which will affect the operation of the ball screw unless accounted for during the selection process.

Mounting:

End supports provide ball screws with stability and rigidity, affecting, in turn, the overall performance and efficiency. Mountings are available in three formats: fixed, simple and free, all which offer different advantages.

Lubrication:

Ball screws generally require regular lubrication to keep them operating efficiently, and so maintenance must be a consideration in selecting your ball screw configuration.

For guidance in selecting the right ball screw for your specific application, it is always advisable to consult with experts in ball screw assemblies. Matara are leaders in linear motion solutions and would be happy to offer support during the design and selection process.