Ball Screws vs Lead Screws

What are the advantages/disadvantages of lead screws?

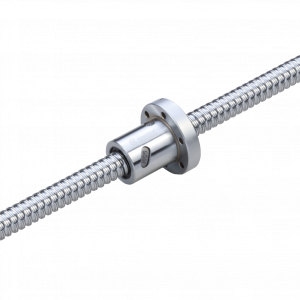

What are the advantages/disadvantages of Ball Screws?

- Ball screws require braking systems.

- Ball screws are available in higher accuracy grades for greater positional accuracy.

- Ball screws are more efficient, requiring less torque.

- Ball screws have lower friction and run at cooler temperatures.

- Ball screws require grease or oil lubrication to achieve design life.

- Ball screws can have higher noise values.

- Ball screws require braking mechanisms to eliminate back driving.

- Ball screws are available in rolled & ground types.

- Ballscrews can be adjusted to increase/decrease preload.

Ball screws vs Lead screws: How does my application dictate which one to use?

Generally speaking, ballscrews are better for applications that require smooth motion, efficiency, accuracy, precision, and prolonged continuous or high-speed movement. Traditional leadscrews are more suitable for transfer applications for which speed, accuracy, precision, and rigidity are not as critical.

Of course, there are always trade-offs to be made depending on your application. In addition to materials, assembly design, and accuracy, important variables to consider include wobble error, noise, maintenance, efficiency, and longevity. In most cases, evaluating the load, accuracy, and lead for your application will most generally answer the question of ball screw vs. lead screw. If you are still unsure on which one to use in your application, please contact our friendly expert team today.