How ballscrews can help motion efficiency

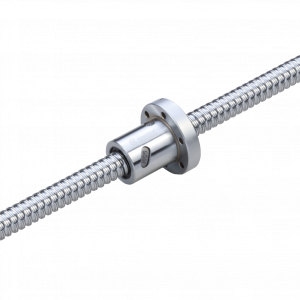

Ballscrew driven linear actuators are an ideal solution where high-precision, accurate linear motion control is required. But how do linear ball screws also ensure a high level of motion efficiency within a motion control system? We take a look at the principles of motion efficiency along with how a ball screw driven linear actuator might help with the efficiency of your motion control systems.

What is motion efficiency?

Motion efficiency (or mechanical efficiency) is the ratio of input energy into a system compared to the energy delivered. It measures the effectiveness of a

machine in transforming the power input to the device to power output. All machines lose energy to friction to some degree, and therefore their power output is always less than their power input. However, when you consider linear motion control devices, a typical linear ball screw would usually be over 90% efficient, versus a 25% efficiency rate provided by a lead screw of equal size.

How do ball screws help with motion efficiency?

The low levels of friction achieved by the use of the ball bearings in a linear ball screw mean that this solution offers much higher levels of mechanical efficiencies when compared to an alternative option such as a lead screw. Not only is the energy requirement lower thanks to the low friction levels within a linear ball screw, but overall efficiency is also improved as a result of the reduced maintenance requirements and less of a need for lubrication.

Is motion efficiency critical in linear motion control?

This depends entirely on your primary goals. If you are considering using a ball screw driven linear actuator for motion control due to its high levels of positional accuracy, the high speeds attainable and the ability of linear ball screws to run at low temperatures for high levels of output, then the motion efficiency is a welcome bonus. However, if you wish to carry a heavy load using linear motion then a ball screw driven linear actuator could potentially be counterproductive as they may be unable to carry heavier loads. Although, ball screw driven linear actuators require considerably less torque and are significantly more efficient due to lower friction levels.

The conclusion, then, is that if a ball screw driven linear actuator is the right solution for your particular application, then you will benefit from motion efficiency, meaning that your system is cheaper to run and operates at optimum levels for less effort on the part of the motor. However, motion efficiency should not be the sole driver for selecting a linear ball screw as your solution.

If you would like to understand more about linear motion control options in relation to your application, or would like to talk to an expert about the linear ballscrews available from Matara, then give our technical team a call on 01684 850000 or email us on sales@matarauk.co.uk.