How pneumatic cylinders improve manufacturing efficiencies

Across many industries, pneumatic systems are implemented in order to create linear motion during an operation sequence. One of the main reasons for using a pneumatic system is that it is a relatively safe option in comparison to electrical solutions and can be used in a variety of hazardous working environments. Furthermore, pneumatic systems often offer a lower upfront set up cost and are relatively easy to maintain and use. A key component of many pneumatic systems is the pneumatic cylinder.

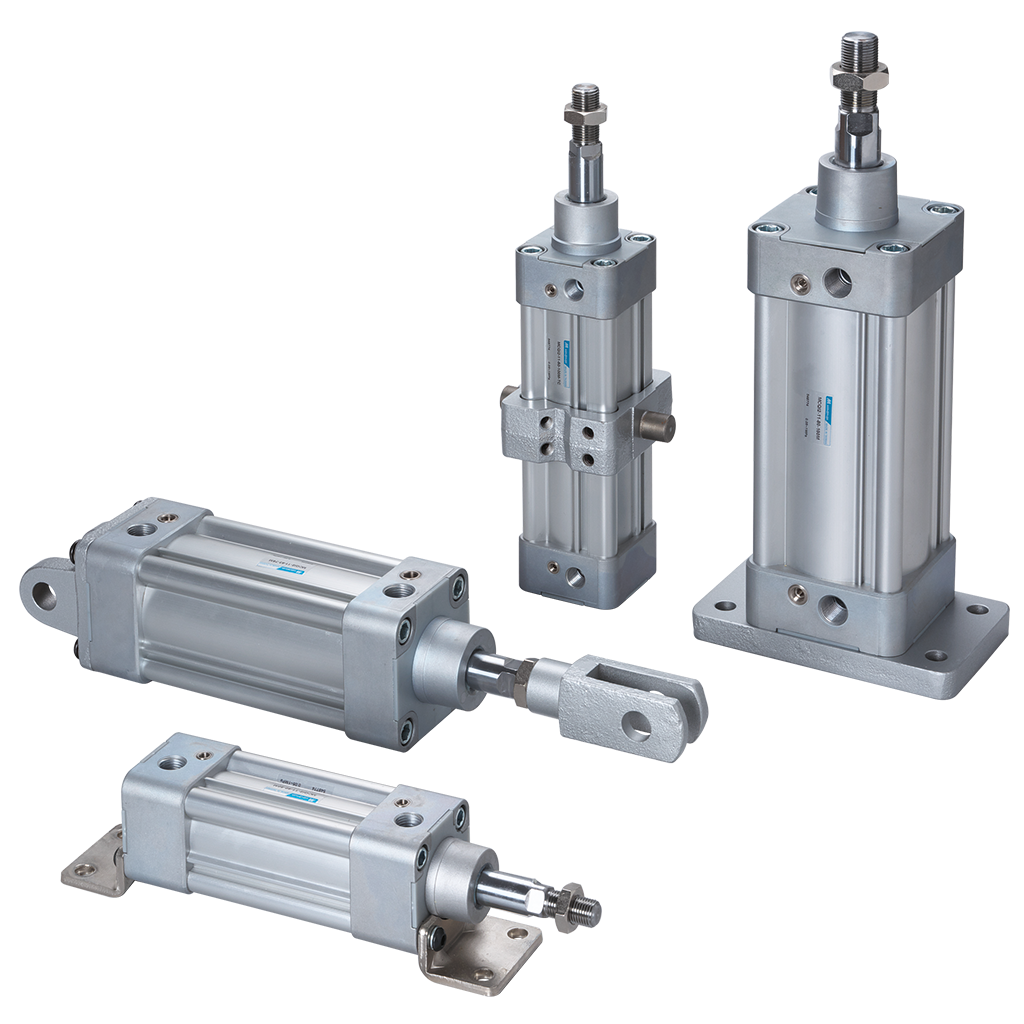

What are pneumatic cylinders?

Pneumatic cylinders, often known as pneumatic actuators, are mechanical devices that convert the energy of compressed air into linear motion. Standard pneumatic cylinders use an extending piston rod and can be either single or double-acting. Single-acting cylinders have air applied to one side of the cylinder, meaning the piston moves in one direction and is returned by using a spring. In a double-acting cylinder, the air is applied to chambers either side of the piston. This means the piston can be moved in both directions, allowing the user to have more control.

Another common type of pneumatic cylinder is the rodless pneumatic cylinder. Rodless cylinders move the required load alongside the piston. This allows for greater space saving as there is no added length from an extended piston rod. Furthermore, linear guides can be fitted to the body of a rodless cylinder, meaning that higher load ratings can be achieved, without running the risk of rod buckling.

How to improve your manufacturing efficiencies

Where manual tasks can be automated or where loads are too great for humans to move, pneumatic cylinders can be installed as a cost-effective solution when compared to human labour. As a result, pneumatic cylinders are in abundance across a multitude of manufacturing facilities.

By automating repetitive manual tasks, many factories can allocate their employees to other business areas, allowing for greater scalability and efficiency of the company in the long run. Furthermore, many pneumatic systems, by using pneumatic cylinders, can be tailored to reproduce performance with the highest levels of precision and repeatability. As a result, accurate production output rates can be calculated, and production forecasts can be easier to compute.

Due to their adaptability and robust nature, pneumatic cylinders carry out a whole host of different functions in different machines across many industries. These include clamping, gripping, positioning, lifting, pressing, shifting, sorting and stacking. In manufacturing industries, pneumatic cylinders will often be used for opening valves, doors, taking things on or off conveyor belts and lifting heavy objects.

How Matara can help

As a manufacturer of pneumatic cylinders for over 24 years, Matara is able to offer a truly bespoke cylinder building service. At the click of a button via the Matara webstore, you can specify the size of your cylinder as well as your stroke length, to the mm, up to 2.8 metres. Furthermore, we are able to offer a wide range of mounting accessories, to accommodate the wide variety of applications cylinders can be fitted in. If you would like to discuss your next project with our team, get in touch with one of our engineers on sales@matarauk.co.uk or telephone 01684 850000.