How to choose the correct ball screw for your application

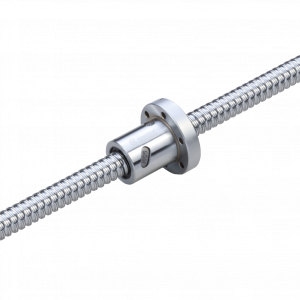

Ballscrews are usually selected for their high-precision linear motion control and their ability to move heavy loads across a distance in a smooth motion at speed. However, there is more than one linear ball screw on the market, and given that you want to choose the one that will give you the greatest return on your investment, it is important to ensure that you select the right one for your application. We take a look at ball screw driven linear actuators and some of the factors to consider when choosing yours.

What types of linear ball screws are available?

Internal return ballscrew: The contained ball return allows the balls to exit the track and directs them into the next thread, returning the ball. It keeps the overall size smaller than other solutions and provides higher accuracy. Less robust than the external return models of linear ball screw, they are not ideal for high load or high-speed applications but are generally found in delicate or high precision applications.

returning the ball. It keeps the overall size smaller than other solutions and provides higher accuracy. Less robust than the external return models of linear ball screw, they are not ideal for high load or high-speed applications but are generally found in delicate or high precision applications.

External return ballscrew: The ball return is external of the nut, usually by the means of a tube, which results in a larger footprint but is much better at dealing with heavy loads. Cleanliness and internal lubrication can be considered as issues with this design. These ball screw driven linear actuators are usually used in high speed and/or high load industrial applications such as process automation or CNC.

End cap return ballscrew: The balls are deflected by an end cap though a route bored transversely down the nut body where the cap at the other end deflects the balls back into the threads. This type of ballscrew is generally quieter and cleaner than other designs and is often used in food preparation and medical applications.

What additional elements should you consider when selecting a linear ball screw?

Accuracy requirements: There are two different methods of manufacturing ballscews; rolling or grinding. Rolled screws use rotating dies to deform metal bars and create the helical thread needed for a ballscrew. Although there are ways that this manufacturing method can be more tightly controlled, this solution is generally considered a cost-effective option that produces a less accurate final product. Ground ballscrews, however, are made by cutting threads into hardened material which produces a much more precise thread with tighter tolerances and lead accuracies – but they come at a higher cost than rolled linear ball screws.

Backdriving risk: Particularly relevant if your load is to be carried vertically, backdriving happens when the motor shuts off and the ball screw free-falls as a result. Brakes must be fitted as a safety precaution in this case. Lead screws, a less efficient alternative to ballscrews, are less likely to experience backdriving and could be a good alternative if you are not looking for the level of efficiency and accuracy offered by ballscrews.

Critical speed: The maximum speed of a ballscrew depends on a combination of the screw diameter, the end fixing type and the screw length. There are standardised ways of calculating this value.

Load: The maximum weight of load that can be carried is dependent on the ballscrew diameter, the end fixing and the free screw length.

Environmental conditions: Although many ballscrews are coated to protect them from damage, if they are operating in conditions where they will be exposed to dirt, debris or chemicals, it may be prudent to protect them from these contaminants. The use of a wiper to prevent contaminants from entering the ball nut is one option, and bellows boots can be used to cover the screw and provide protection that way.

Lubrication: Operating temperature and frequency of use both impact the need for lubrication, which must be maintained at all times in order to facilitate an efficient output and extend the lifespan of your ball screw driven linear actuator. Maintenance should be a consideration when selecting the right ballscrew for use.

Matara offers a range of both rolled and ground ballscrews, all available for viewing on our website. However, if you would like support in selecting the right linear ball screw for your application, our expert team would be happy to talk through the options with you. Contact us now on 01684 850000 or email sales@matarauk.co.uk to arrange a chat.