Key factors to consider to ensure precise linear motion

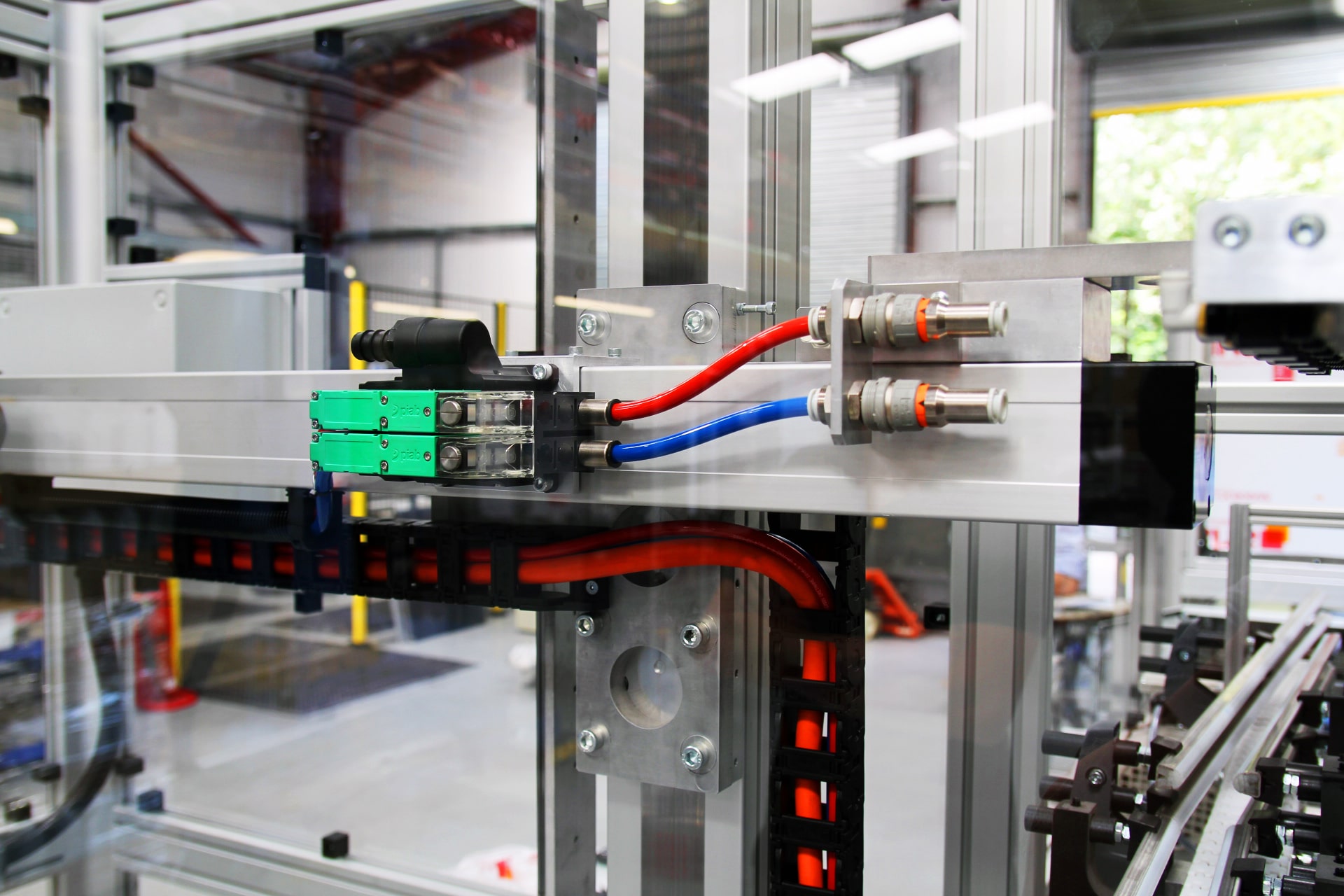

Linear motion is generally intended as a precision operation, replacing the need for human

Travel accuracy

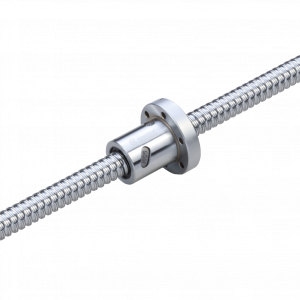

When considering travel accuracy for linear automation products, both the linear rail and the carriage can have an impact. Travel accuracy includes the restriction of movements up and down and side to side, as well as rolling around the axis. Ensuring alignment of the linear rail(s), suitable mounting equipment for both stability and flatness, as well as correctly toleranced linear rails and carriages will all add to the travel accuracy. You can also look at the actuator selected;, for example, linear ball screws are available with specialised runner blocks and optimised ball recirculation to reduce the impact of vibration. Although linear ball screws are, in themselves, extremely accurate in the precision movement that they provide, they can still impact the equipment around them if not specified properly.

System rigidity

Rigidity is critical because in order to avoid unwanted problems such as production errors, unintentional movement of your linear automation products must be prevented – and having a system which is rigid enough to prevent movement will eliminate these kinds of issues. The type of linear rail chosen – steel or aluminium – as well as the profile and thickness, all affect rigidity. Equally, mountings and fasteners, as well as any preload applied, and ensuring that firm end supports are used on thrust mechanisms, will impact the rigidity of the system and therefore its precision. The actuator can also influence the precision of the system through rigidity; when linear ball screws are used, the length of the screw drive will affect the stiffness of the overall system because the longer the screw selected, the more difficult it can be to compensate for deflection.

Speed

If speed is a critical factor in your application as well as precision, an additional challenge is inevitably created. Processes with short cycle times and high speed requirements can push the capabilities of both linear rail guides and linear ball screws. A ball screw has a ‘critical speed’, which is where it goes beyond its standard operational speed and begins to vibrate unacceptably. End bearing support systems for linear ball screws can aid the level of critical speed, as can the type of mounting selected and the length of the shaft of the ball screw. ‘Characteristic speed’ also impacts precision, and relates to the ball nuts within the linear ball screw.

Thermal considerations

Most linear automation products are manufactured from materials that expand in length when their temperature is increased and contract when the temperature decreases. This creates potential problems in maintaining precision within a linear motion control system, particularly when you consider that different parts of an axis can be subject to different temperatures depending on the forces, cycles and running times that they are experiencing. Deformation as a result of this thermal impact can create misalignment as well as friction, affecting output and also potentially producing

more heat. There are solutions available to help to stabilise temperature – such as the use of a pillow block in a linear ball screw assembly – however, these solutions impact rigidity. They can be combined with fixed bearings to provide additional support. Similarly, advances in drive components and control systems means that much of the thermal impact can be compensated for when designing a linear automation system.

Machine resonance

Vibration within linear automation products and systems will likely impact the precision of the work being undertaken by the equipment and therefore the quality of the end product. All of the areas identified above contribute to machine resonance, although other factors can also play a part, such as system backlash or vibration from external sources such as HVAC systems and other nearby equipment creating resonance. When designing and positioning your linear automation system, other machinery that is either adjacent to, or working with, your automation system should also be considered.

If you are designing a linear motion control system and would like advice on linear automation products or how to select the best linear ball screw or linear rail for your application, get in touch with Matara; we would be delighted to help you to achieve your optimum in precision and control, selecting the most effective components for your application. Call us now on 01684 850000 or email sales@matarauk.co.uk.