Linear rails Vs. Linear rods – which are better?

Linear rods and linear rails ultimately perform the same function; they are both a part of a system used to move a load in a straight line from one point to another using an actuator. However, there are more subtle differences that separate the two in terms of choosing one over and above the other for a specific application. We take a look below at linear rail actuators and linear rods and consider their relative benefits for different applications and purposes.

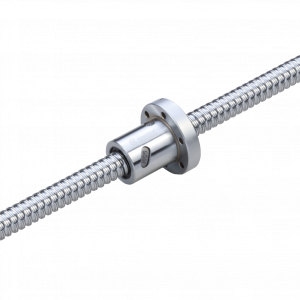

What is a linear rod actuator?

Linear rod actuators generally use either pneumatic or electric power to move their load to the intended final position. A linear rod actuator extends the load beyond the body of the actuator.

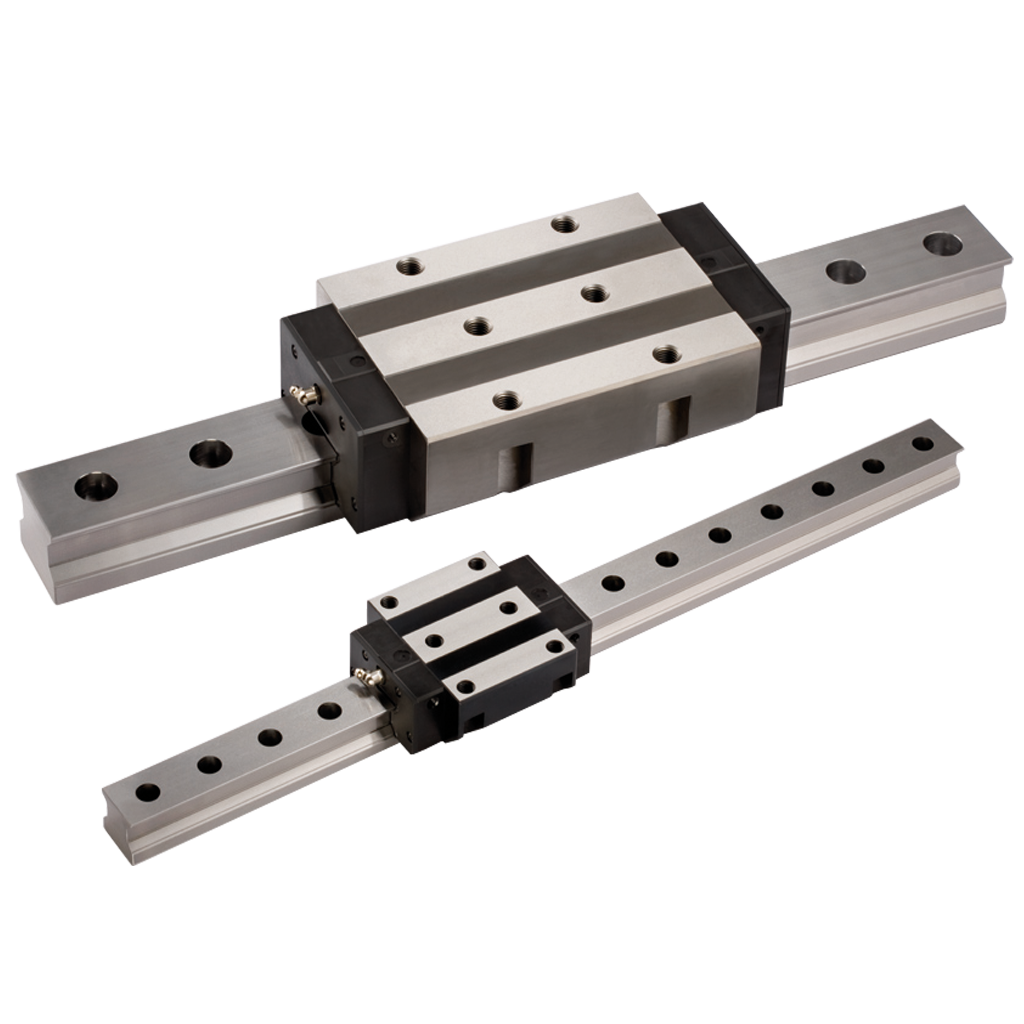

What is a linear rail actuator?

A linear rail is an actuator where the load is contained within the body of actuator (the travel length of the load is within the dimensions of rod), and therefore the load travels along the linear rail. The linear rail itself is a rigid rail, usually manufactured from stainless steel and containing ball bearings that create contact points between the carriage and the rail which help to create a smooth motion along the linear rail.

Matara supplies both rod and rail electric actuators, so what are the advantages of each?

Linear rail actuators:

Space saving. A linear rail solution means that the whole assembly is no longer than the rail itself, meaning that if space is tight and you cannot afford additional equipment on top of the available length of travel, a linear rail actuator may be a better solution.

High rigidity. The linear rail has much less flex than a linear rod thanks to its profile. This enables the linear rail actuator to move much heavier loads than a linear rod.

No load rotation. A linear rail is a more stable platform than a rod, meaning that a load won’t rotate during movement, providing a more accurate and steady result. Linear rods can be doubled up to prevent rotation, but a linear rail therefore provides a lighter, simpler solution.

High accuracy. Linear rails are generally manufactured to much tighter tolerances than linear rods which means that they are less likely to flex during operation, and the movement of the carriage is smooth and consistent.

Made to measure. Because bespoke linear rails are available to be cut to the exact length required, the travel distance can be calculated and catered for to fit an exact requirement.

Linear rods:

Hygiene levels. Linear rod solutions are sealed units and are therefore generally better for clean environments such as food and drink or pharmaceutical production. They can also be cleaned with high pressure sterilisers.

Longer reach. If you need to push something further than the cylinder length, or use it to integrate with other moveable parts or equipment, then a linear rod solution would be the better choice as there is not a permanent rail assembly in place.

Affordability. Linear rods are generally a more affordable option than a linear rail actuator solution.

The conclusion is that linear rod and linear rail actuators, whilst on first glance seeming very similar in that they perform the same function, are in fact suited to very different applications. If you are looking at an electric linear actuator then, chances are, a rod or a linear rail solution would be a good fit, but which one is right for you will depend on your working environment and industry, the load specifications, the movement parameters and the space available. If you would like guidance in selecting the right solution, whether you want a bespoke linear rail actuator or a linear rod solution, contact Matara and talk to one of our experts on 01684 850000.