What applications do linear rail solutions suit?

What is a linear rail?

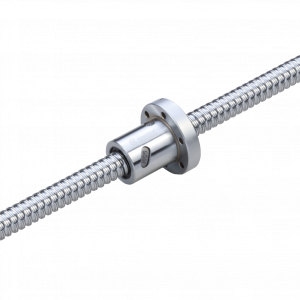

Simply put, linear rail are common linear motion components that allow for smooth movement of loads along one axis. Each linear rail is cut to a specified length and includes mounting holes at certain distances, known as the pitch, for easy installation. Furthermore, when combined with linear guides, which are made to fit a certain size linear rail, you create what is known as a linear rail system.

Linear guides incorporate a ball bearing circuit that runs along the grooves of the linear rail. This helps to lessen the friction between the guide and the rail, allowing for a more efficient and accurate solution. Additionally, linear rail has a great load-bearing capacity per size ratio when compared to other common linear motion solutions. For example, a single PMI linear rail 15mm carriage can take a static load of 18.9kN and a dynamic of 11.8kN.

Additionally, linear guides also have mounting holes, so that you can fix the load that the rail is transporting. Due to the friction countering design, heavy load bearing capacity and the ease of installation, these linear rail systems are used in a wide variety of industrial applications across many different sectors. We will discuss these further along in this article.

As a further note, due to the common nature of this product, it has many different names throughout different industries. To help, here are a few of the most common terms: linear guideway, linear rail solutions, linear guide rails, linear rail slide, linear guidance systems.

Benefits of using PMI linear rail slide

- High positioning accuracy, high repeatability.

- Low frictional resistance, meaning that a high level of precision can be maintained for a long period.

- High rigidity, for load-bearing in four directions.

- Low friction allows for use in high-speed applications.

Applications that use a linear rail system

At Matara, we hold a large stock of different sized linear rail and carriages here in the UK. With a large design and machining facility, we are able to provide an unrivalled level of project support. With over 25 years’ worth of experience, we have provided linear rail systems to applications in a wide variety of different industries. Some of the most common applications are as follows:

- Pick and place systems

- Support systems for actuators used in XYZ Gantry systems

- Runners for industrial doors

- Runners for train doors

- As a support guide for Rodless Cylinders

- Machine tools

- Cartesian robots

How do you specify a linear rail?

When choosing a linear rail slide there have always been a number of external factors to consider, such as load, speed, repeatability, environmental conditions and cycle times. In order to define what you require, the best place to begin is by highlighting the most critical elements of your design that need to be met. If you require any help with this, Matara’s team of design engineers are on hand to help you choose the correct linear rail system for your application. You can get in touch with our friendly, expert team on sales@matarauk.co.uk.