What is a linear rail actuator and what applications do they suit?

Linear rail actuators are commonly found across a whole range of industries and are used for moving loads from one point to another. Linear rail actuators offer an advantage over other linear actuators by providing a high-rigidity, four-way equal load-carrying ability. We take a look here at linear motion systems, how a linear rail actuator works, and what kinds of applications they might be used in.

What is an actuator?

An actuator is designed to move a load, usually powered by hydraulics, pneumatics or electricity. The applications that actuators are used in vary from enormous earth-moving equipment in a construction or mining setting, through to tiny precision movements required in the manufacture of electronic components. A linear actuator is designed to move loads in straight lines; forward and/or backward, up and/or down. Linear motion systems are often powered by hydraulics or pneumatics as these inherently produce linear motion, however, where precision and control over acceleration and deceleration is required, electric motors are often used to create linear motion from a rotating motor.

An actuator is designed to move a load, usually powered by hydraulics, pneumatics or electricity. The applications that actuators are used in vary from enormous earth-moving equipment in a construction or mining setting, through to tiny precision movements required in the manufacture of electronic components. A linear actuator is designed to move loads in straight lines; forward and/or backward, up and/or down. Linear motion systems are often powered by hydraulics or pneumatics as these inherently produce linear motion, however, where precision and control over acceleration and deceleration is required, electric motors are often used to create linear motion from a rotating motor.

Linear rail actuators

A linear rail actuator is, essentially, a rodless actuator that uses either single or parallel rails for the motion guide rather than a solid body as you would find in a standard linear actuator. A linear rail actuator is made up of a stationary base and load bearing carriage which travels along a rigid rail, usually aluminium. One of the more common rail actuators found in linear motion systems is a linear ball screw actuator.

What is a linear ball screw actuator?

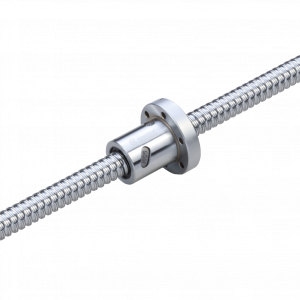

A linear ball screw is a mechanical type of linear rail actuator. A threaded shaft provides a helical raceway for ball bearings which are contained within the load mount. They have very low internal friction and are by their nature built to high precision, so they provide excellent accuracy and repeatability. The reduced friction means they have a much higher mechanical efficiency than a standard screw and nut combination. A linear ball screw actuator unit is also capable of carrying greater loads and achieving a higher thrust force than other types of linear actuator.

Benefits of a linear rail actuator

- Complete end-to-end axial stability

- Precise accuracy

- Contact angle of 45 degrees so that it will bear an equal load in radial, reversed radial and lateral direction

- Loads are easy to attach to the carriage

- Smooth movements

- Low noise output

- Self-alignment capability

- Available in specialist configurations such as wide load and heavy load capability, reduced height, miniature and compact options

Applications for linear rail actuators

Linear motion systems are used in many industrial settings, and the rail configuration found in linear rail actuators lends itself to high stiffness for stability, as well as low-friction guidance, with loads ranging from very lightweight at just a few grams through to thousands of kilograms. They are also not limited in travel length as compared to other linear actuators. This makes them applicable to almost any industrial environment where loads must be moved in a straight line over distances. Some examples of applications for linear rail actuators are:

Overhead transport systems: loads can be centred beneath the rail and bearing block, allowing for the transportation of heavy loads around a factory setting.

Machine tools: travel accuracy and stability are key to the requirements of machine tools, often combined with heavy loads. This makes a linear rail actuator ideal, particularly where dual rails are used to ensure the minimum of deflection.

Gantry robots: often with two or three rail axis working in parallel to ensure greater moment capability, gantry – or Cartesian – robots use rails, often with a linear ball screw actuator, to enable movement across the X, Y and Z-axis. Used in processes from packaging to semi-conductor manufacture, these devices are found in many industrial plants.

Processing environments: with electrical linear rail actuators being both clean and quiet, they are ideal for industries such as food and drink, medical device manufacture or electrical manufacturing. Linear rail actuators have few places for bacteria or dirt to accumulate and will manage the clean-down process without issue.

Matara are experts in linear motion systems, with nearly 25 years in the industry, offering a complete solution for a whole range of environments and applications. We have a variety of linear rail actuators, both for standard use and specialist applications, and also offer a bespoke service for custom requirements. Get in touch to talk to us about what you need in a linear motion system and we will work with you to get you the right result. Tel 01684 850000 or email sales@matarauk.co.uk.