What linear motion control options are there?

Linear motion systems are used widely in industrial automation for one specific type of motion control: the task of moving parts of a machine in a controlled manner in a straight line. Linear motion applications include the control of machine tools, assembling and packing, test and inspection and in robotics systems. In this article, we look in more detail at linear motion systems, including some of the more common drive technologies used for linear motion such as lead screws and ball screw linear actuators.

What is a linear motion system made up of?

Linear motion systems usually consist of a controller (either a computer or a stand-alone electronic device), a motor and the actuator which moves the load. When we talk about linear motion, the specification is for the load to be moved in a straight line, either up and down or back and forth. This sounds straightforward, but when you consider that a common solution for moving small loads accurately and with precision would be an electric motor, because of the rotary nature of the motor, the actuator must be able to turn rotational movement into linear movement.

What drive technologies are there for linear motion systems?

The most common solutions are ball screw linear actuators and lead screw drives.

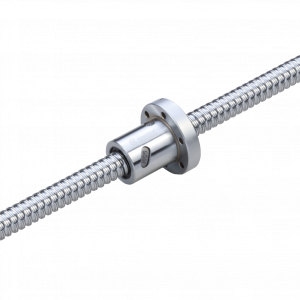

Ballscrew linear actuators:

A ball screw linear actuator converts rotational motion into linear movement using a threaded shaft and ball bearings. The shaft of the ball screw includes a helical path around which the ball bearings move, behaving like a screw but with very little friction; the ball assembly behaves as the nut, with the threaded shaft acting as a screw. Manufactured to higher tolerances than some of the other linear motion drive options, ball screw linear actuators are a popular choice for high precision applications where accuracy and control are critical. The main drawback of ball screw linear actuators is that due to the need for the balls to be recirculated, the overall size of the device is larger and bulkier than other options.

Lead screw actuators:

Lead screws are designed in the same way as ball screw linear actuators, except that rather than having ball bearings to provide a frictionless motion, the lead screw’s thread maintains direct contact with the moving nut component. This means that whilst higher forces are possible with a lead screw, the added friction creates the need for more power from the motor. However, the added friction of the leadscrew can lead to less efficient systems. This in turn, may lead to increased running and maintenance costs overtime. The other advantage with lead screws is that they are less prone to being back driven and do not require an additional braking component in the way that ball screw linear actuators do for some linear motion applications.

Linear motion systems from Matara

There are a range of options for linear motion control from Matara, including lead screws and ball screw linear actuators with either rolled ball screws or ground ball screws. We also offer linear guides and rails to be used for support and guidance in linear motion systems, which are designed to be used in conjunction with a screw assembly or an alternative linear motion drive.

If you would like to know more about the range of linear motion systems on offer from Matara, call one of our experts now on 01684 850000 or email sales@mataruk.co.uk.